Advances in Post Processing for Additive Manufacturing

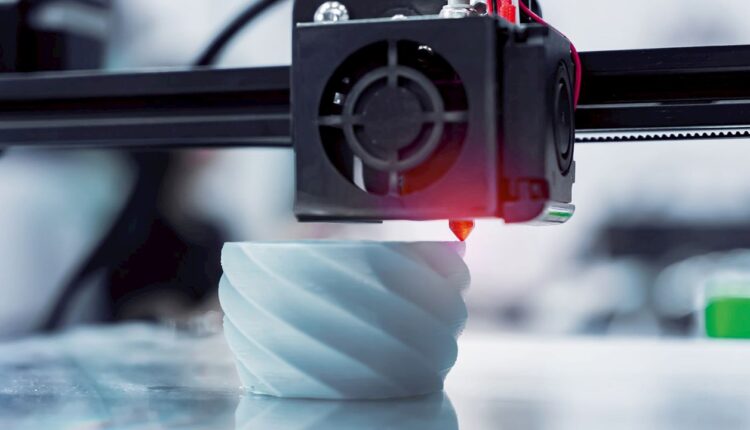

3D printing, sometimes called additive manufacturing, has completely changed how we make anything from complex jewelry to aerospace components. However, the narrative is far from over when the printer stops working; what follows is just as important. This is where post-processing becomes a crucial but sometimes overlooked step in the 3D printing process. Let’s explore the fascinating world of additive manufacturing post processing and the latest advances that are making waves.

The Crucial Function of Post-Processing

Imagine that a 3D printer has completed creating an item. Although it’s a triumphant moment, it still needs to be prepared. Here’s where post-processing comes into play. An object that has just been produced becomes a polished jewel from a rough diamond thanks to the unsung hero. Various methods, such as cleaning, polishing, painting, or heat treatments, are used during post-processing to enhance the printed object’s strength and appearance. Imagine it as the distinction between an unfiltered, raw snapshot and a painstakingly manipulated work of art.

Reaching New Heights

Innovation in additive manufacturing’s post-processing space is booming. These are a few of the most noteworthy developments:

The Post-Processing Automation

Automation transforms the game. Imagine devices that require little assistance from humans to not just print but also clean and finish the items. This breakthrough translates into quicker turnaround times, more reliable quality, and the capacity to manage intricate jobs that prove difficult for manual post-processing.

Eco-Friendly Solution

People all over the world are increasingly concerned about the effects of technology on the environment, and additive manufacturing is no exception. Oddities that are harmless to the ecosystem post-handling methods arose, for example, utilizing water-based paints to get done or biodegradable synthetic substances for cleaning. In addition to being environmentally friendly, these developments frequently result in safer and better workplaces.

Advanced Surface Polishing

Although surface polishing has always been an essential part of post-processing, new technologies are making it even more critical. We are talking about ways to make super smooth surfaces, which are essential for the aerospace and medical technology industries. Chemical smoothing and intricate sanding techniques are two examples of these methods used to enhance the final product’s appearance and functionality.

Customized Post-Processing

In many industries, personalization is critical, and additive manufacturing post-processing is no different. More personalized finishes, such as distinctive textures or color schemes, are now possible thanks to new technology. Since fashion and consumer products place a high priority on uniqueness, this trend is exciting.

Integrated Quality Assurance

How could we guarantee the quality of the product after it has been processed? This is turning into a reality with headways in coordinated quality control frameworks. By using sensors and artificial intelligence to find flaws or anomalies in the finished product, these technologies ensure that only the best products leave the factory.

The Impact on Organizations

These improvements in post-handling make an expansive difference. They improved post-processing results in safer and more dependable medical devices and implants in sectors like healthcare, where precision and quality are unquestionable. In the aviation sector, enhanced surface finishes have the potential to enhance aerodynamics and fuel efficiency. In addition, the speed with which high-quality products can be made and customized is altering our perspective on the production of consumer goods.

Final Thoughts: Looking Forward

Post-processing in additive manufacturing has a promising future ahead of it. Automation is probably in store, with artificial intelligence (AI) becoming increasingly important in the production and post-processing phases. Eco-friendly methods will be standard operating procedures, and as integrated systems advance in sophistication, the distinction between printing and finishing will become increasingly hazy.

Comments are closed.